e ngineering

a brighter future

NEWS

08 May 2025

The world of engineering is constantly evolving, so the way we approach doing things must also change. In 2025, we are utilising advanced technology more than ever in nearly every part of our lives, including engineering apprenticeships. CNC machining apprenticeships prepare apprentices to work with complex and beneficial technology that’s becoming more prevalent in New Zealand and the rest of the world.

While engineering was mostly a hands-on job in the past, in 2025, many tasks are performed by machines. Engineers must learn and master these machines. Advanced machinery can ensure accuracy, consistency, and satisfactory results.

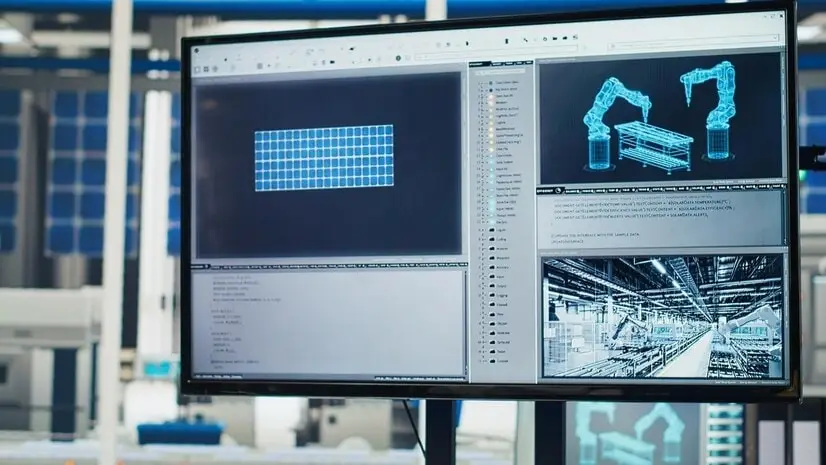

The acronym ‘CNC’ means ‘Computer Numerical Control,’ and CNC tech refers to the computerised operation of machining tools used for manufacturing. Essentially, these CNC machines work with computer software and codes that tell each component exactly what to do. Instead of a manual operator controlling these tools with their hands, the machines are controlled with pre-programmed codes so they can work automatically.

Why does this matter for apprentices? As an apprentice, you aren’t just training for today’s work – you’re training for the rest of your prosperous career. Technology is sure to grow and evolve even more in the future, so you’re future-proofing your role as an engineer by embracing digital systems now. Learning about these crucial components now prepares you to adapt alongside technology as time goes on.

CNC technology in engineering features a few key principles:

These core principles mean that CNC machinery is exact, flexible and able to repeat tasks over and over with consistent results. CNC technology in engineering lends itself well to complex designs and intricate geometries that would otherwise be difficult to handle with manual machining.

Overall, CNC machining apprenticeships prepare apprentices to work with these complex machines. As an apprentice, you’ll learn more about coding the machinery, how the machines are commanded by the programming given, how to read sensors and feedback, etc.

CNC technology is so prevalent in 2025 that it’s being used throughout countless industries. The aerospace, automotive and medical fields are just a few industries that are benefiting from this advanced tech.

With how prominent and useful CNC tech is, it’s no surprise that engineering apprenticeships can strongly benefit from learning more about it. Working with CNC technology is a must-have skill for modern engineering professionals and apprentices alike. Learning how to operate and maintain CNC machines will give you a strong advantage in the workforce.

Training With CAD And CAM Software. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are core tools for modern engineers. Getting started with these platforms now enables you to design, simulate and plan components and tasks with confidence. Advanced digital tools provide clarity, making it easier to work with even the most complex plans.

Reading Real-Time Feedback. A major advantage of CNC machines is that they can provide you with real-time insights into how they’re functioning. This clarity reduces guesswork and makes it much easier to diagnose problems and fine-tune operations. This will help you avoid costly, frustrating errors while deepening your technical understanding.

Merging Hands-On Learning With Technology. Although we perform manual tasks less frequently now than we did in the past, engineering as a whole is still a very hands-on industry, just in a different way. Instead of building something entirely by hand, you’ll be physically working with machines that can do the work for you.

You can gain practical experience by using machines and tools that experienced engineers use every day, learning precisely how to use them while building muscle memory.

This blend of practical experience with modern digital tools will allow you to become a well-rounded engineer. You will build your physical and mental coordination at the same time.

Having Clarity With Digital Documentation And Workflow Management. Precise digital tools simplify the process of communicating with others, managing projects, planning designs and so much more. You will learn how to work with software that modern engineers use every day, preparing you for countless projects down the track.

Engineering is constantly evolving, and so are we at ATNZ. We help apprentices build their careers with our accessible engineering courses. We welcome all kinds of learners to apply, including people of all genders, races and backgrounds. We’re proud to support Maori, Pasifika and women learners who want to step into the engineering industry.

You can start the process by booking a chat with us at .

ATNZ: Advance your skills and your career with our CNC machining apprenticeships.